Cost Savings At Swindon Apartment Block

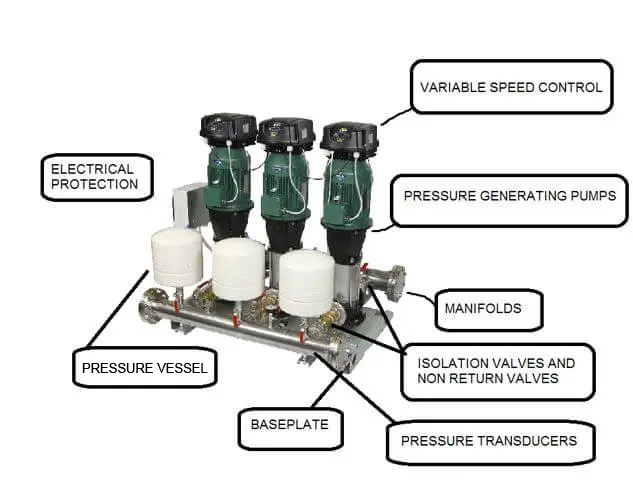

A facility management company reached out to us regarding one of their managed properties. The site was an apartment block in Swindon, and the problem at hand was not functioning correctly, causing increased costs. After a careful inspection, our engineers concluded that the problem involved the Variable Speed Drive(VSD), the Non Return Valve and there was also a safety issue which was not suspected by our client.

The Challenge

After attending the site, our engineers discovered that the Booster Set wasn’t the problem, but a Variable Speed Drive and a Non-Return Valve were faulty. This meant the Booster Set Pump was working 24 hours, 7 days a week, and instead of saving money, the pump was actually working constantly, resulting in increased energy costs and over time – wear of the equipment. Further to that, they discovered another fault in the system, which might have had dire consequences. The pressure vessels did not have drain cock on them. This creates a couple of risks:

- Risk of stagnant water in the vessel, which creates an environment with an elevated risk of Legionella.

- Lack of ability to drain the vessel in order to ensure that it has the correct pre-charge. Each booster set has a particular set point based on the facility which it is servicing and if that is not adjusted, the safety of the pumps is compromised.

The Solution

Because the site had a twin variable booster set, we needed two VSDs, as they both needed to be able to communicate with each other. This would not be possible if we changed only one of the VSDs because the installed units were old, and installing only one VSD would not be a viable solution, as it would not be compatible with the old unit.

We were able to install the new VSDs, Non Return Valve and the drain cock whilst giving the whole system a service within a day, minimising disruption and ensuring the site is back working efficiently.

What is a VSD? Maintained correctly, a VSD is designed to control and protect pumping systems by changing the motor frequency and pump speed. It is connected to the pump and will control its operation, to maintain a constant desired performance (e.g. pressure, flow, temperature, etc). Utilising a VSD can result in a 20% reduction in speed, providing up to 50% reduction in energy used.

Results

The facility managers were extremely happy with our service as the apartment block was able to benefit from energy and cost savings, increased pump life, greater reliability (i.e. water is always the same temp. or if demand is high for water, the same water pressure is achieved) and improved safety.

Talk to the Experts

Are you looking for a reliable and quick care for your pumping systems? Call Mawdsleys Pumps now on 0117 954 8030 to talk to a member of our expert team. We are available 24/7 and will provide you the full picture.