Dirty water pumping systems are used in a variety of situations when gravity can’t carry the water, these include pumping waste in a private property into a main sewer, drainage at a commercial yard, waste plants, dirty water transportation on farms and yard run off. The type of pump you will have will be based on your need and dependent on the flow, pressure and distance you wish to pump waste water.

Autumn can be a difficult time if you have a dirty water pump on your premises. A common cause of failure in autumn is blockages due to the excess amount of falling leaves and a general increase in the amount of rainfall. There is never a good time for your dirty water pump to fail and regular maintenance is essential to ensure this doesn’t happen.

Common Problems with Dirty Water Pumping Systems

Pump tripping the MCB (miniature circuit breaker) – this can be a sign that water has entered the winding of your pump, you can expect excess rainfall over Autumn in comparison to Summer, therefore this problem might be more likely to arise throughout this upcoming period. This problem can be easily resolved with a pump rewind – our dedicated rewind shop in Bristol means we can have your pump back up and running quickly.

Problems with your Phase Convertor – Over time the phase convertor in your pump can fail, this problem can be identified by pump underperformance or complete failure. To resolve this problem, we can overhaul your phase convertor at a fraction of the cost of pump replacement.

Blockage by rag – This is one of the most common causes of failure we find in submersible pumps. In some cases they can result in complete stoppage leading to costly downtime and potential pump damage.

Floats sticking – This is caused by grease build up around the floats, it can be reduced by using a grease trap – this is designed to naturally separate out and fats and grease from waste water.

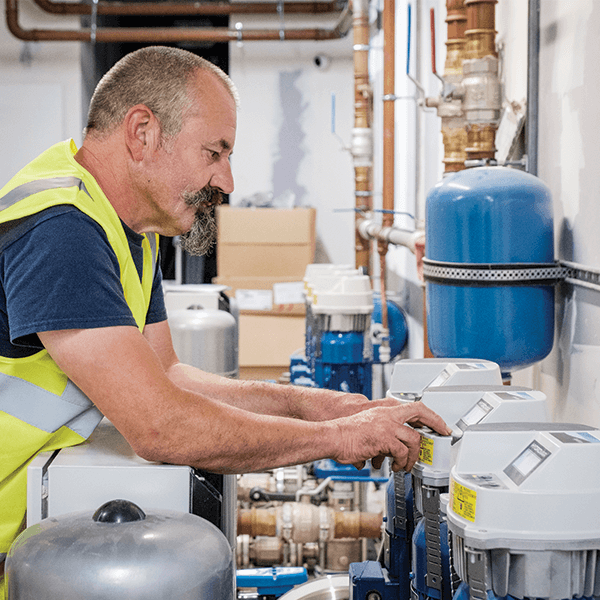

Regular Pump Maintenance Plan

All of the above issues can be avoided with a maintenance plan, where all the elements of your dirty water pumping system are checked, maintained and replacement parts fitted before the pump actually fails. It is always better to prevent a pump failure than wait for it to happen. Not only will you avoid downtime but you reduce the risk of damage to the pumping system which would be more costly than replacing a worn part.

Early indication of possible pump/motor failure can be diagnosed during routine maintenance procedures, mechanical seals and O rings can also be checked and early notification can also prevent costly seal failures and downtime.

Agricultural Dirty Water Pumping Systems for Farmers

Following ‘Brexit’, there is a little uncertainty for UK farmers as to whether they will have the same subsidies that have been provided by Brussels, after we leave the EU.

At Mawdsleys Pump Services, we have worked with farmers for many years and we know the agricultural industry. In light of these potential financial losses you may experience, we can offer practical and cost effective solutions to your water disposal needs based on a site visit with a full survey and no obligation quote provided. Our dirty water pumping systems come with a 2 year guarantee and 24 hour breakdown call out service.

Our Dirty Water Disposal System

Talk To Our Expert Team Today

If you need advice or guidance on how we can assist you in managing and maintaining your dirty water pump, or are interested in a free, no obligation quote based on your needs. We cover a vast majority of the South West from Bristol and Bath to Dorset and Cornwall – Give us a call on 0117 954 8030.

The first named storm of the season has hit the UK.

The first named storm of the season has hit the UK.

Horse riding arenas, equestrian centres and ménages both indoor and outdoor require water to suppress dust when in use. Airborne dust in the arena can cause both health and performance hazards to horse and rider. Because of this, dust suppression is an absolute priority for equestrian centre owners.

Horse riding arenas, equestrian centres and ménages both indoor and outdoor require water to suppress dust when in use. Airborne dust in the arena can cause both health and performance hazards to horse and rider. Because of this, dust suppression is an absolute priority for equestrian centre owners.